|

Shanghai HJ clean room Co.,LTd

|

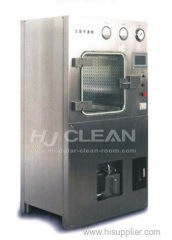

Industrial Clean Drying Oven

| Payment Terms: | T/T,L/C,D/A,D/P,WU,Paypal,Money Gram |

| Place of Origin: | Shanghai, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

This clean drying oven is used for baking products with chemical smell and products in food processing industries, for substrate stress removal, etc.

This clean drying oven is used for baking products with chemical smell and products in food processing industries, for substrate stress removal, for ink curing and drying of paint film, etc. It's widely used for precise baking, drying, tempering, preheating, setting, processing in electric, electromechanical, communications, electroplating, plastic, hardware&chemical, food, printing, pharmaceutical, PC board, powder, soaking, coating, glass, ceramics, wood construction materials, and so on.

Technical parameters

1.Cleanliness grade: Class A~D

2.Temperature range:20---150 ℃

3.Lowest humidity:10%RH

4.Temperature uniformity:± 2 ℃

5.Pressure control: -100Pa--+100Pa

6.Machine surface temp.:no 8 ℃ higher than room temp.

7.Power supply: AC220V±22V/ AC380V±22V 50Hz±1Hz

8.Power consumption: Customerized (6KW—10KW)

9.Overall dimensions: can be customerized according to customer's requirement

10.Validation items: temperature, humidity, temperature uniformity, humidity uniformity, heating time, drying efficiency

Features

1, keep working area clean:fresh air and return air mix and return back to the workspace through HEPA filter, cleanliness can reach class A dynamically.

2, fast dehumidification function: optimize the design of exhaust efficiency and evaporation temperature, to achieve a dynamic balance.

3, highly efficient dehumidification equipment: adopt energy recovery mechanism to recover energy from wet air and then preheat fresh air thus to reduce energy consumption of equipment.

4, environmental protection: air exhausts through HEPA filter to ensure no pollution to external environment.

5, temperature uniformity: the design of the uniform airflow structure ensures uniform heating temperature and uniform airflow temperature in the tank to achieve uniform moisture evaporation and even drying.

6, intelligent control: PLC closed-loop control to ensure the temperature, humidity, air displacement, drying efficiency and clean environment within automatic control.

7, the air flow pattern: can make vertical uniflow or horizontal uniflow according to customer's actual needs.