|

Shanghai HJ clean room Co.,LTd

|

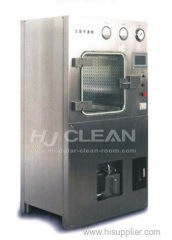

Clean room mist shower

| Payment Terms: | T/T,L/C,D/A,D/P,WU,Paypal,Money Gram |

| Place of Origin: | Shanghai, China (Mainland) |

|

|

|

| Add to Basket | Add to My Favorites |

| HiSupplier Escrow |

Product Detail

MAS-800 automatic mist shower,fully developed by our company, is a new photo-electric interlocking automatic mist shower with PLC control.

Automatic pharmaceutical clean room mist shower

Introduction

MAS-800 automatic mist shower,fully developed by our company, is a new photo-electric interlocking

automatic mist shower with PLC control. It is widely applied to pharmaceutical, biochemical production

sectors and hospital isolation wards. The working principle of this mist shower is to wet the dust first

and then blow the dust off, then the operator can take off the working outwear and leave the production

sector to avoid the spread of potent substance outside clean room. This mist shower is effective in

decontamination of operators and preventing the outside air being polluted by the untreated potent dust.

Structure

MAS-800 automatic mist shower uses SUS304 steel plate, equipped with centrifugal fans, mist nozzles,

bag-in-bag-out filter system, and assembled HEPA filter mist/air blowing & filtration system.

It is characterized by well formed&compact structure, easy maintenance, simple operation, etc. This machine

adopts PLC controlled infrared probe, automatic mist spray/air blow and electric interlock.

Process of entering clean area

When an operator open the entrance door manually, the exit door will close at the same time and the light turns on, then the operator enters into the air shower room and closes the entrance door. When the photoelectric sensor senses the operator, the mist shower starts to spray mist(mist shower time adjustable). When the mist shower ends the air shower begins(air shower time adjustable). When the air shower ends, the exit door automatically unlock, then the operator can open the exit door and leave the air shower room.

Notice:

1)During mist/air shower, the both doors are powered on and locked, can't force opening.

2)When one door is opened, the other door will be automatically locked and closed, the two doors are in interlocked state to avoid contamination from lower cleanliness area.

Technical parameters

1.Filtration efficiency:>=99.99%@0.5μm(sodium flame method)

2.Air shower time:1~99seconds adjustable(default 20s )

3.Mist shower time:1~99seconds adjustable(default 20s )

4.Mist particle size:10~50um

5.Spray nozzle air speed:≥20m/s

6.Mist shower nozzle no.:6

7.Air shower nozzle no.:6

8.Overall dimensions:1150W×1000D×2100 H

9.Air shower area:800W×900D×1950H

10.Power:3N 380V 50Hz

11.Max power consumption:1KW

12.HEPA filter size:610×610×70×1pc

13.BIBO:650*650*1000MM

Maintenance

1.Check each technical index of the air shower at regular intervals,it needs to be taken care timely if the index doesn't meet the technical requirements.

2.Regularly wash the primary filter cartridge(normally 3 months) according to actual usage.

3.When the air gets slower, user should first check the primary filter. Too much dust on the filter surface will increase air flow friction, user needs to change a new filter.

4.If air speed is not improved after changing or washing primary filter, then the HEPA filter must be blocked and needs change.

5.Before replacing the used HEPA filter, nozzle plate needs to be dissembled first and the new HEPA filter should be the same size and model as the used one. The HEPA filter should be installed with the arrow mark pointing to the air flow direction to get good sealing effect.

6.After changing the HEPA filter, user should check and make sure there is no leakage around the filter frame and use particle counter for air monitoring to ensure the filter meet technical requirements before it put into use.

7.Check the electrical circuit regularly. If there is a failure, repair according to the electrical schematic diagram.

8.Conduct maintenance to the two doors regularly.

9.This mist shower room must not be operated in the temperature higher than 50℃, and open flames are prohibited.