|

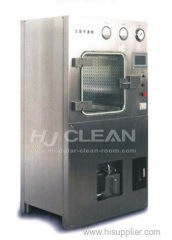

Shanghai HJ clean room Co.,LTd

|

Large Flow remote laser particle online monitor

| Payment Terms: | T/T,L/C,D/A,D/P,WU,Paypal,Money Gram |

| Place of Origin: | Shanghai, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

Particle online monitoring system is used to record the existence state of the suspended particle in air of the the key area in the production line.

Applications

Clean-room Verification

Clean Bench Verification

IAQ Investigation

Food Process Investigation

Hospital Surgical Room

Filter Testing

Multi-point Real-time Monitoring System is widely used in the fields of pure monitoring, pure clean, pure packing, equipment authentication, equipment surveillance, monitoring SMIF, drug packing and manufacture, outer covering semiconductor, hard disk manufacture, aerospace, surgical ward in hospital, and equipment and installment in hospital.

Introduction

The Particle online monitoring system is used to record the existence state of the suspended particle in air of the the key area in the production line,it can automatically and continuously monitor and record the distribution of the size and quantiy of the suspended particle in the monitoring environment ,and produce reports at the same timewhen the state of the particle in the monitoring environment exceed the alarm limit and the rectification limit ,the system can automatically stimulate the acousto-optic alarm,to inform the related personnel to deal with ,thus help ensure that the particle state is normal in the key environment of the monitoring ,and to ensure the smooth production.

This system is established according to the related standard of the GMP,and according to the requirement and standards of the FDA and EU GMP. mainly contain the parts as following:

Y09-SS suspending particle monitoring transmitter,

Vacuum system(containing double pump which complement each other ,air storage tank ,and filter)

Alarm system (containing alarm limit and the rectification limit),alarm handling,results analysis,recording and print.industrial control software recording report ,curve generation ,monthly report(by curve ,)yearly report(by curve)

Description of the System

1.Continuously monitoring of the clean room

Suspending particles monitoring transmitter is composed laser detector and SS power evenly speed sampling pump, use center vacuum pump to support the power of air suction ,the air flow rate is set to be the same standard air flow rate(28.3L/min)by the flow detector of each sensor.

All the sampling pumps and detectors in a SUS304 shell, prevent the outer pollution effectively, and it also make the sampling convenient to sterilize and clean.

When sterilizing, it can change from the online monitoring into the state of sterilizing automatically, starts the sterilize pump, sterilizing the evenly speed sampling pump sampling tube with out influence the sensor.

2.Center vacuum system

The entire system adopting work and spare type vacuum pump, each pump can support enough air suction capacity for all the sampling points, the system attaches automatic transfer device, it can make another pump go to work when occurs unusual condition of the working pump, it also can make sure that it will not affect the regular work when routine inspection or there occurs problems of the pump.

3.Alarm

Audible and visual alarm installs in a conspicuous place, it can provide audible or visual signal and alarm could change into 3 color types of signal light(red, yellow, green),every color represents a kind of alarm. Red means the number of airborne particle over the limit; yellow means the number of airborne particle over the guard line; green means the number of the airborne particle is in a safety limit. Meanwhile, the alarm attaches a buzzer to provide audible alarm.

4.Software, data connection and transmission

All the software system is designed to be a closed local area network, the data of the number of the particle outputted by suspended particles monitoring transmitter reach computer and PLC, then the computer and PLC deal with the data such as data communication, save, compare, alarm, report form etc.

This unit of system sets the online airborne particle monitoring, sampling pump by the user's assembly line, continuously monitoring the size channels 0.5um and 5.0um of clean grade Class A area. The system equipped with outer vacuum sampling pump, so that can equip all the necessary accessories such as sampling pump tubes, wire and power wire in accordance with the physical truth of the factory. All the wire pass through the stainless steel tubes, extend and make it come true to monitor the environment parameter of clean grade class A area and class B area in each clan room at real time, including temperature ,humidity, pressure, wind speed; And it combine the function of display, record, save, print, alarm and history data query.

| Outside Dim | 227*251*159 mm3(Wide*Deep*High) |

| Weight | 4kg |

| Max. Consumption | 40W |

| Power Source | DC 24V |

| Size Channels | 0.5,5.0μm |

| Flow Rate | 28.3L/min |

| Environmental Temperature | 10-40degree celsius |

| Humidity | 20%-90%RH |

| Atmosphere Pressure | 86Kpa-106Kpa |

| Detection cycle | Can set (1 second to 24 hours) |

| Zero Count | 10min |

| Data output mode | RS-485 OR 4-20mA OR modbus |