|

Shanghai HJ clean room Co.,LTd

|

Laminar flow trolley for cleanroom

| Payment Terms: | T/T,L/C,D/A,D/P,WU,Paypal,Money Gram |

| Place of Origin: | Shanghai, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

Laminar flow trolley adopts adjustable air quantity fan system, by adjusting in the working condition of the fan.

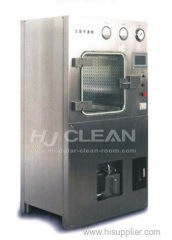

Class A laminar flow trolley for cleanroom

Function brief

This laminar flow trolley(clean transfer vehicle) is an equipment which brings built-in DC power, motor up

an down, provides local environment that clean grade is class A, and can move; it has a widely application

in pharmaceutical industry, the medicine transfered from the exit of canning to freeze-dryer, and the

transfer of the workers appparatus used to transfer the medicine box into the canning line; can butt joint

to the canning RABS and clean protection butt joint to freeze-dryer speedily, seamlessly, and efficiently,

which guarantees the medicine transfer and connection in the class A area.

Construction specification

Laminar flow trolley adopts adjustable air quantity fan system, by adjusting in the working condition of

the fan. The laminar flow trolley can make the average wind speed in the clean work area keeps

in rated range(0.45m/s), keep the clealiness and positive pressure condition in the working area.

According to air flow direction, the laminar flow trolley is divided into two types vertical flow trolley

and horizontal flow trolley. Vertical air flow: the air flows from top to bottom, pass through the lift

platform round and the PC embosom platform, to form a positive differential pressure between the interior

and exterior, to ensure the class A clean grade in the working area during the moving process of the

mobile clean vehicle(laminar flow trolley).

Laminar flow trolley adopts motor elevator mechanism drive moving platform, which can stop at arbitrary

position up or down. There are location limit switches to ensure the platform moves between the highest

and lowest position.

The four sides of the laminar flow trolley have PC to embosom, up and down movable doors on two sides, to

ensure the joint port can open the butt joint at the same time when the laminar flow trolley joint to the

isolate embosom and the airtight and positioning.